|

|

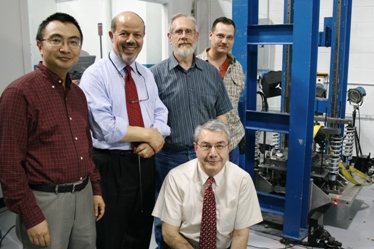

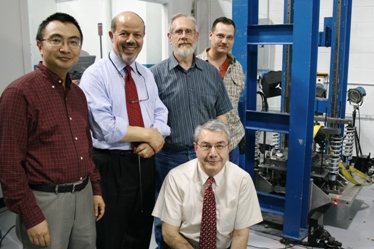

The FAJRI team: Dr. Xianjie Yang, Dr. Sayed Nassar, Dr. Michael Latcha, Matt Bruer, SECS Labs Manager and Dr. Mehment Uras.

|

This spring, Oakland University’s Fastening and Joining Research Institute (FAJRI) unveiled the successful results of a TARDEC research project that was nearly two years in the making, and has the potential to save lives.

In fall 2010, FAJRI received a $1 million grant to develop a system that reduces the impact of an IED attack on a heavy military land vehicle. The goal is to diminish the loss of life and limb of military personnel when engaged in an attack situation.

“Six months ago, we didn’t know if the technology would work at all, or if it would even be possible to solve the problem,” said Sayed Nassar, Ph.D., director of FAJRI and professor of engineering. “We have tried many ideas that did not work, but with lots of fine tuning, we have reached our goal. We are very excited.”

The test demonstrated the ingenuity of FAJRI’s researchers, who achieved results above and beyond

those they

|

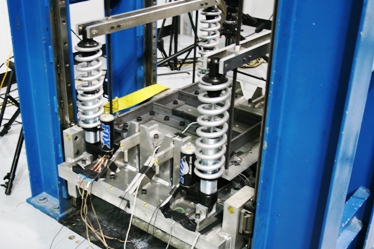

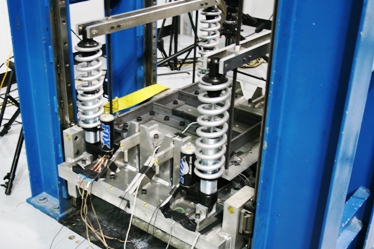

| The drop tower simulation demonstrated the success of FAJRI's design. The team was able to reduce the force of impact by 60 percent and uncouple the vehicle's floor in .0004 seconds.

|

were tasked with. The team developed a false floor in the vehicle to absorb much of the shock of an IED blast, initiated through a system of small chemical explosive devices.

The success of the drop tower simulated vehicle test has pushed the project ahead. The next step is to build an 8 x 8 full-scale model that will be sent to Baltimore for a final test at the end of July.

Charged with reducing the force of impact in the cab by 50 percent and uncoupling the vehicle’s floor in .0008 seconds (about the speed of a hummingbird’s wings), FAJRI researchers managed to reduce the impact by 60 percent and uncouple the floor in .0004 seconds.

“It works every time,” said Michael Latcha, Ph.D., FAJRI researcher and associate professor of engineering. “The test has been remarkably repeatable. You would think that running something so fast would create a great variable of results, but our design is very stable and robust, which is exactly what is needed to deploy in the field.”

There were several obstacles leading up to the final design and test. For example, the system must be set to trigger only during an actual IED blast, to ensure that it doesn’t initiate when the vehicle simply hits a bump. The team then managed to design a device that stops and contains all projectiles accelerated from the initiator device in just fractions of a second.

“We are able to stop a bullet in about a quarter of an inch of space. It’s very cool.” Dr. Latcha said.

FAJRI’s task is one component of a larger project designed to reduce the impact of explosives on the occupants of a military vehicle. Other organizations received TARDEC assignments to diminish the force of a blast even further, such as padding for the cab and suspension issues.

The team collaborated with AUTOLiv, a local company that makes the systems used to deploy air bags in cars, a mechanism they have utilized in the final project design.

The congressionally-approved FAJRI is the only known facility of its kind in the world. To learn more about the institute,

view the website.